As the paper vs. digital war continues, the manufacturing industry is always searching for new ways to produce, buy, and sell environmentally friendly, sustainable products and other goods.

If you consider yourself to be conscious of the materials and the production process regarding the goods you buy, (i.e., are the materials and the production eco-friendly?) then you should also be worrying about the kinds of energy-efficient technologies the manufacturing industry has their hands on!

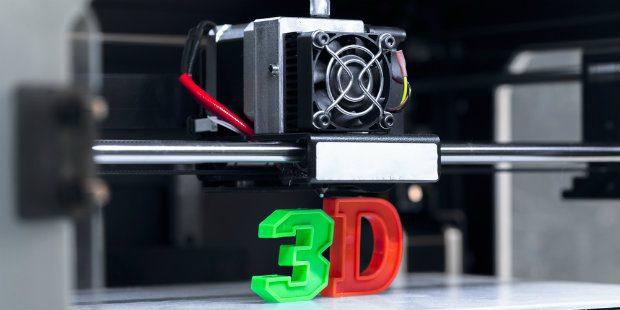

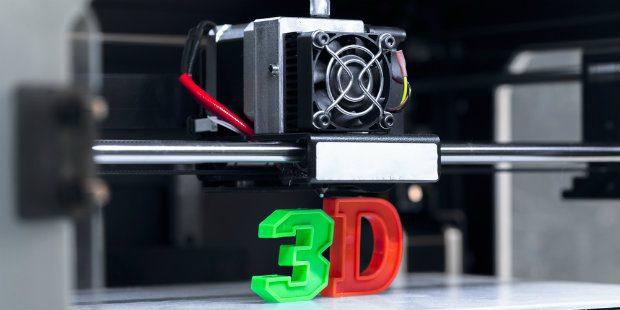

So let’s talk 3D printing- and I know what you’re thinking, it sounds like something from a science-fiction movie, right?

3D printing is a method of printing by means of “printing” or making an object from layers of liquid plastic into a three-dimensional digital model by joining these materials together.

Although 3D printing has been most common in the automobile industry as of late, forward-thinkers in aerospace, medicine, and even some retailers and school’s are hopping on the bandwagon.

While it may take some time to find 3D printers in everyone’s home, having the ability to “print” items on demand will soon be a thing of the present, accessible to most.

But what does this mean for the environment?

Let’s weigh in on the environmental pros and cons of 3D printing:

Pros

- Since 3D printing is ideal for large scale consumers, certain 3D printers use environmentally friendly materials such as recycled plastic, wood-based composite and more, allowing fewer raw materials to be used.

- If 3D printers are implemented in home’s, manufacturers can reduce the cost of transportation and transportation pollution being emitted into the air.

- 3D printers in the home also cancel out any possibility of needless manufacturing.

- 3D printers have the ability to “print” parts that are 50% lighter than others, reducing fuel costs overall.

- If a part of your bicycle breaks, 3D print it! 3D printers could also mean longer lives for certain products.

Cons

- A fair amount of energy is used to power a 3D printer (specially if the application requires low-layer thickness and high-temperature materials). *** The energy must come from a renewable source.

- 3D printers rely heavily on plastic, which is never good for the environment. (However, researchers are indeed working on creating biodegradable plastic polymers, or ink!)

- Some 3D printers emit ultra-fine particles (UFPs) that emit toxic second-hand fumes that could be potentially harmful to both humans and animals.

Solutions

To minimize the cons of 3D printing, make sure to research the different printing approaches and options, examine the environmental factors before printing or having someone print, and study how the products design requirements could impact the environment and other processes.

With the global 3D printing industry expected to grow to $18.4 billion in 2020 (McAlister and Wood), it is clear that 3D printing technology is here to stay. It’s up to us to evolve them into more efficient, environmentally friendly, sustainable machines.

Are you up to the challenge?

References:

McAlister, Catriona and Wood, Jonathan, “The potential of 3D printing to reduce the environmental impacts of production,” eceee 2014 Industrial Summer Study.

Leave a Reply

You must be logged in to post a comment.